Description

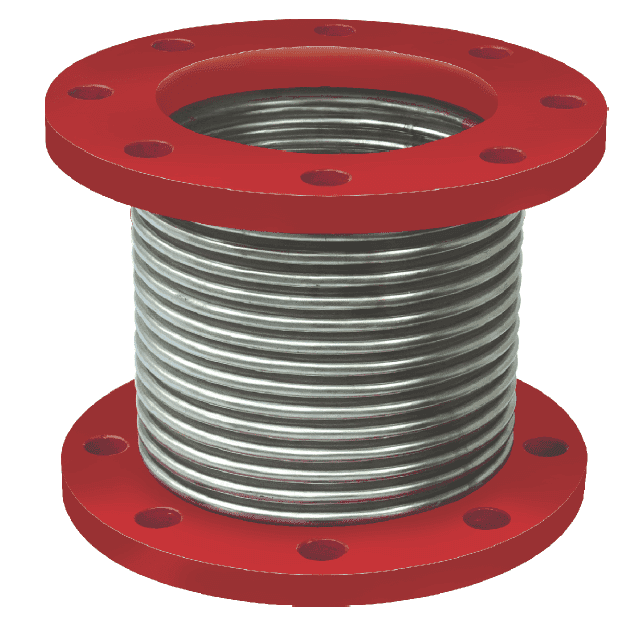

Exhaust Bellows – High Temperature Engine Exhaust Expansion Bellows

Overview

Exhaust bellows are specialized metallic expansion joints designed for diesel generator exhaust systems, engine exhaust pipes and high-temperature gas applications. Manufactured from high-grade stainless steel (304/316/321), these bellows absorb thermal expansion, engine vibration and misalignment in exhaust systems operating at temperatures up to 650°C and beyond.

Features

- High-temperature stainless steel construction

- Single or multi-ply bellows for pressure containment

- Flanged or butt-weld end connections

- Can include flexible pipe sections

- Designed for pulsating exhaust flow

- Corrosion-resistant materials

- Manufactured to EJMA and international standards

Applications

- Diesel generator (DG set) exhaust systems

- Gas generator exhaust connections

- Industrial engine exhaust piping

- Marine engine exhaust systems

- Boiler breechings and flue gas connections

- Turbine exhaust systems

- Incinerator and furnace exhaust

- High-temperature process gas piping

- Emergency generator exhaust in buildings

Technical Specifications

- Material: Stainless Steel 304, 316, 321, Inconel, Duplex

- Temperature: Up to 650°C, up to 1000°C

- Pressure: Typically low pressure, up to 0.5 bar in exhaust systems

- Size Range: DN25 (1″) to DN1200 (48″)

- Bellows Type: Single-ply or 2-ply for safety

- End Connections: Fixed flanges, floating flanges or butt-weld

Why Exhaust Systems Need Bellows:

- Thermal Expansion: Exhaust pipes expand significantly (steel expands 12mm per meter at 500°C).

- Engine Vibration: Running engines create substantial vibration requiring flexible connections.

- Misalignment: Building settlement or foundation movement needs compensation.

- Acoustic Isolation: Flexible bellows reduce noise transmission through exhaust piping.

- Stress Relief: Prevents stress on engine exhaust manifold and silencer connections.

Construction Types

Basic Exhaust Bellow: Stainless steel bellows with flanges, suitable for moderate temperatures.

Braided Exhaust Bellow: Outer stainless steel braid protects bellows and improves appearance.

Flexible Exhaust Pipe: Long corrugated flexible pipe (up to 3 meters) with or without braid.

Design Considerations

- Exhaust gas temperature (peak and average)

- Engine vibration amplitude and frequency

- Thermal expansion of exhaust piping

- Back pressure requirements (low restriction)

- Flange standards (ANSI, DIN, custom)

- Installation space and routing

- Indoor or outdoor installation

- Required service life

Benefits

- Accommodates thermal expansion in hot exhaust systems

- Isolates engine vibration from exhaust piping

- Reduces stress on engine exhaust manifold

- Prevents exhaust system failures and leaks

- Allows flexibility for engine movement

- Reduces noise transmission

- Long service life in high-temperature applications

- Corrosion-resistant stainless steel construction

Contact RMS Corporation with engine/generator specifications (kVA rating, exhaust temperature, pipe size, flange type) for exhaust bellow selection and supply.