Description

Cylindrical Mounts (O Mounts) – Versatile Rubber Vibration Isolators

Overview

Cylindrical mounts, also known as O mounts or bobbin mounts, are simple yet effective rubber vibration isolators consisting of a cylindrical rubber element bonded between two metal plates with threaded studs. The design provides vibration isolation in compression, tension and shear, making them suitable for a wide variety of applications.

Features

- Simple cylindrical rubber-metal bonded construction

- Dual-stud design allows compression and tension loading

- Isolation in multiple directions (compression, tension, shear)

- Compact and lightweight design

- Cost-effective vibration isolation solution

- Available in numerous sizes and rubber hardness grades

- Standard metric and imperial stud threads

Applications

Cylindrical O mounts are used in:

- Industrial machinery and workshop equipment

- Small pumps, fans and motors

- Automotive and vehicle applications

- Electronic equipment and control panels

- HVAC equipment and small air handling units

- Laboratory and medical equipment

- Marine and transportation vibration isolation

Technical Specifications

- Material: Natural rubber

- Stud Types: Male-male, male-female, female-female

- Standard Sizes: 15mm to 100mm diameter, 10mm to 120mm height

- Load Range: 5 kg to 150 kg per mount

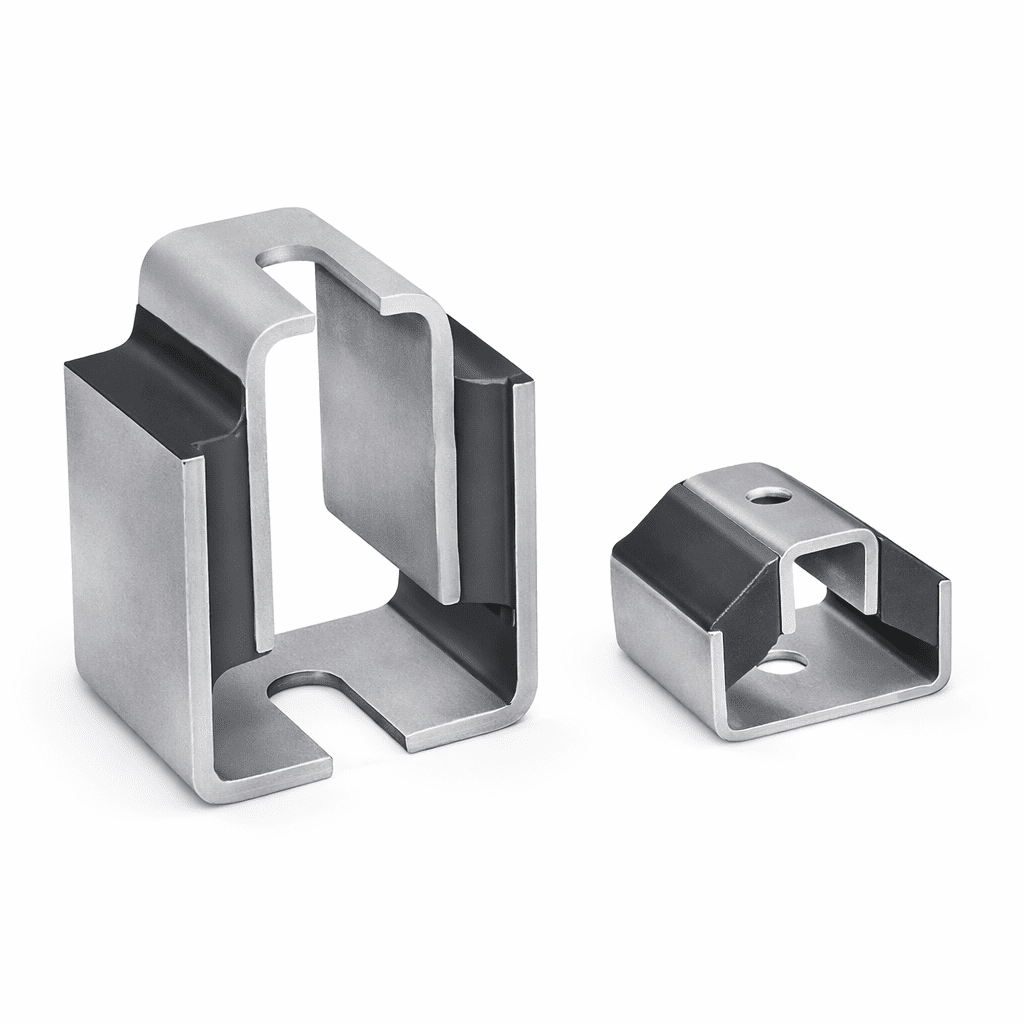

Common Mounting Configurations

Male-Male (Type 1):

Threaded studs on both sides, equipment bolts from top, base bolts from bottom.

Male-Female (Type 2):

One threaded stud, one threaded insert. Provides different mounting flexibility.

Female-Female (Type 3):

Threaded inserts on both sides. Bolts thread into mount from both directions.

Benefits

- Versatile mounting options for various configurations

- Good vibration isolation for light to medium loads

- Resistant to oils, chemicals and weathering

- Easy to install and replace

- Wide selection of sizes and load capacities

- Can be used in compression or tension

- Long service life with minimal maintenance

Selection Guidelines

Choose cylindrical O mounts based on:

- Equipment weight and number of mounting points

- Type of vibration (frequency and amplitude)

- Operating environment (temperature, chemicals)

- Mounting configuration (space constraints)

- Rubber hardness for required deflection

Contact our team for O mount selection assistance and vibration isolation calculations.