Description

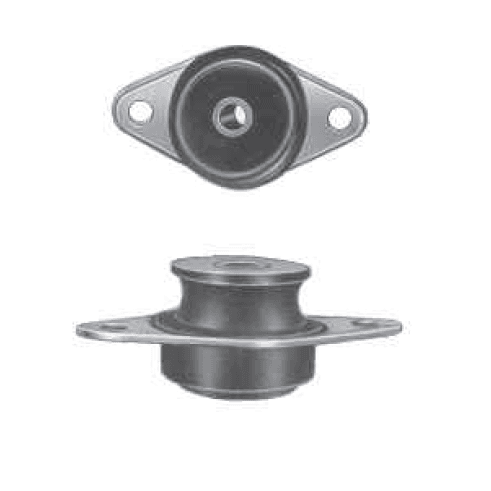

Core Mounts – Rubber Vibration Isolation Mountings

Overview

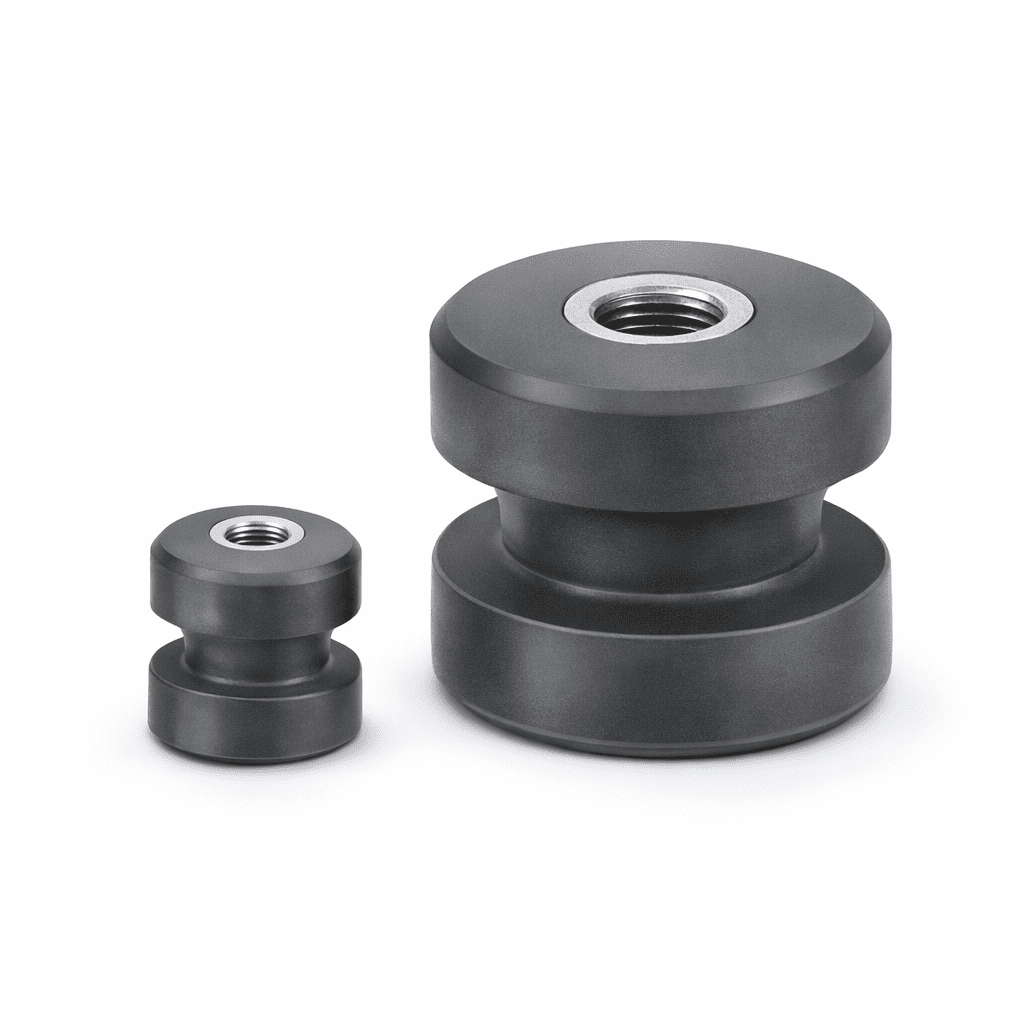

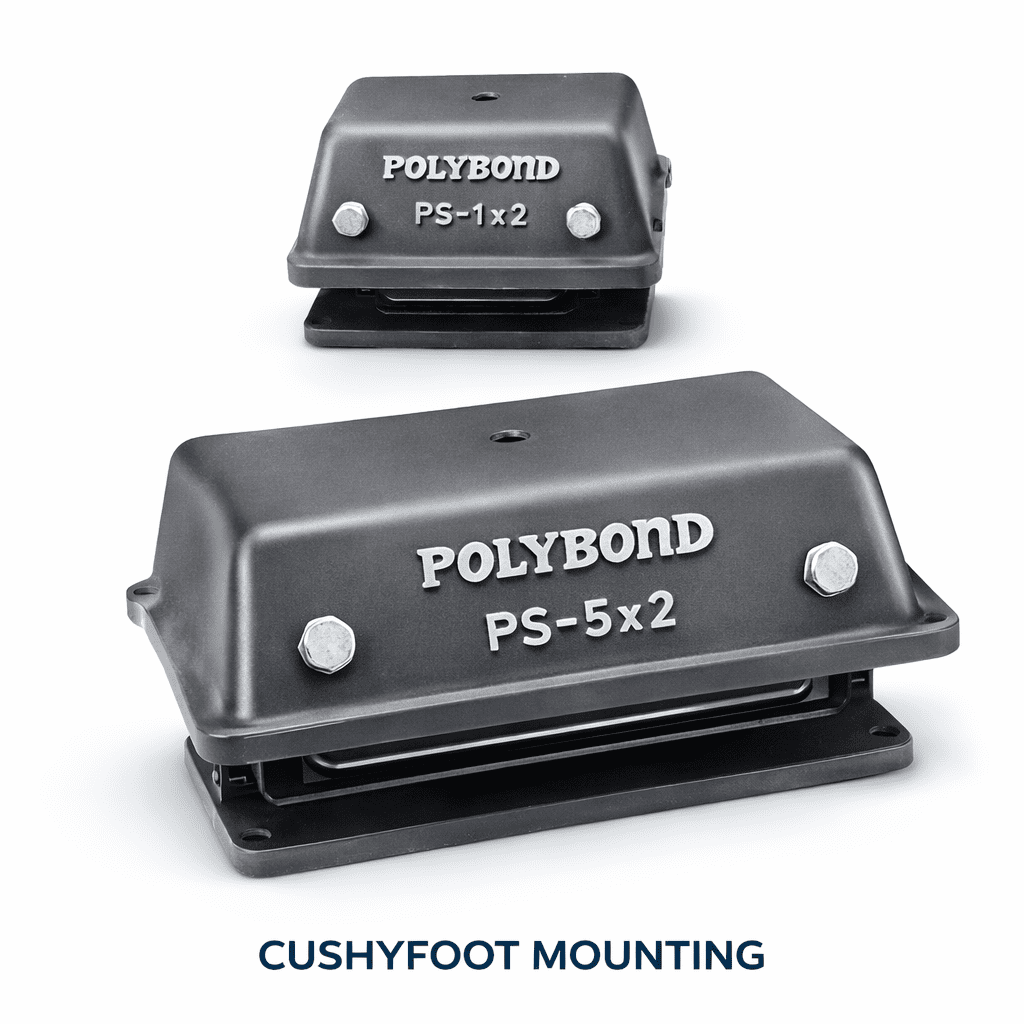

Core mounts are cylindrical rubber-metal bonded vibration isolators designed to provide reliable vibration isolation for compressors, pumps, fans and general industrial machinery. The rubber core is compression-molded and bonded to metal plates or flanges, providing excellent load-carrying capacity and vibration damping in a compact mounting.

Features

- Cylindrical rubber core bonded to metal plates

- High-quality rubber compounds for long service life

- Compression and shear vibration isolation

- Rugged steel components with corrosion protection

- Multiple mounting configurations (male/female studs)

- Wide range of load capacities

- Suitable for indoor and outdoor applications

Applications

Core mounts are widely used for:

- Radiator mountings

- Frame Mounted Equipment

- Electric motors and motor-driven machinery

- Small generators and power equipment

- Engine Mountings

- Industrial machinery and processing equipment

- Earth Moving Equipments

Technical Specifications

- Material: Natural rubber, neoprene or nitrile rubber compounds

- Metal Components: Steel with zinc plating or epoxy powder coating

- Load Range: 25 kg to 400 kg per mount (multiple sizes available)

- Deflection: 1.5mm to 6mm under rated load

- Natural Frequency: 10-15 Hz depending on load and model

- Temperature Range: -30°C to +70°C (standard), -40°C to +100°C (special grades)

- Mounting Options: Male-male studs, male-female studs, through-bolt designs

- Standard Stud Sizes: M8, M10, M12, M16

Benefits

- Effective vibration isolation reduces structure-borne noise

- Extends equipment bearing life by reducing transmitted vibrations

- Compact design fits in tight installation spaces

- Easy to install with standard tools and fasteners

- Long service life – typically 10-15 years in normal conditions

- Cost-effective vibration isolation solution

- No maintenance required during service life

Selection Guidelines

Proper core mount selection depends on:

- Total equipment weight (including motor, driven equipment, base frame)

- Number of mounting points (typically 4 to 6)

- Operating speed/frequency of equipment

- Desired vibration isolation efficiency

- Environmental conditions (temperature, chemical exposure)

- Available mounting space and configuration

Contact RMS Corporation with your equipment details (weight, dimensions, operating speed) for proper core mount selection and vibration isolation calculations. Our technical team can provide layoutdrawings and installation recommendations.