Description

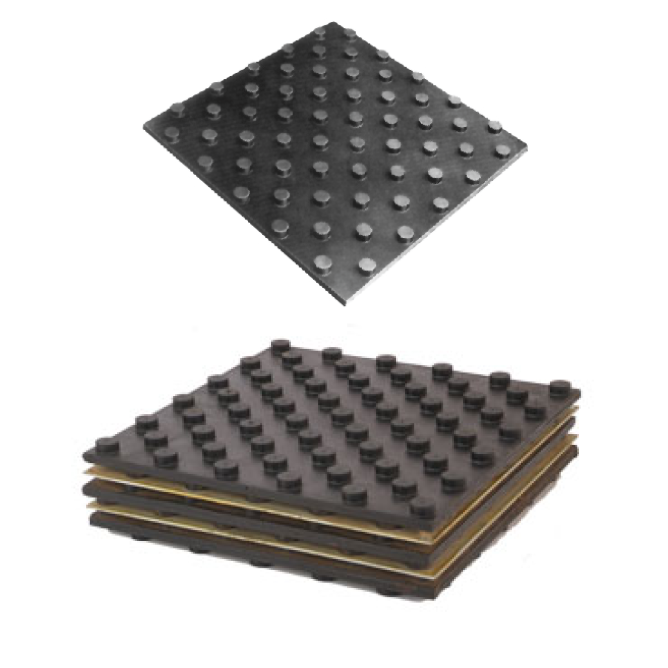

Compression Stud Pads – Rubber Anti-Vibration Mounting Pads

Overview

Compression stud pads are molded rubber anti-vibration pads with integrated threaded studs for easymounting. These pads provide effective vibration isolation by allowing the rubber to deform in compression, absorbing and damping vibrations from equipment. The ribbed or studded design increases the rubber’s flexibility and improves isolation efficiency.

Features

- Molded natural or synthetic rubber construction

- Integrated metal studs for simple bolt-down installation

- Ribbed or studded rubber pattern for enhanced flexibility

- High damping to reduce vibration transmission

- Resistant to oils, chemicals and weathering

- Non-marking rubber compound

- Available in various sizes and hardness grades

Applications

Compression stud pads are used under:

- Small air compressors and vacuum pumps

- Fans, blowers and exhaust systems

- Workshop machinery and bench-mounted equipment

- Electrical panels and control cabinets

- HVAC equipment (fan coil units, small AHUs)

- Printing and packaging machinery

- Laboratory equipment and instruments

Technical Specifications

- Material: Natural rubber, neoprene or nitrile rubber

- Hardness: 40 Shore A to 70 Shore A (multiple options)

- Stud Sizes: M6, M8, M10, M12 threaded studs

- Pad Dimensions: Various sizes from 40mm to 150mm diameter

- Load Capacity: 20 kg to 200 kg per pad depending on size

- Deflection: 1mm to 5mm under rated load

- Temperature Range: -20°C to +80°C

Benefits

- Cost-effective vibration isolation for light equipment

- Quick and easy installation

- Reduces floor vibration and noise

- Protects sensitive equipment from external vibrations

- Long-lasting rubber with excellent resilience

- No maintenance required

Contact RMS Corporation for compression stud pad selection and vibration isolation advice.