Description

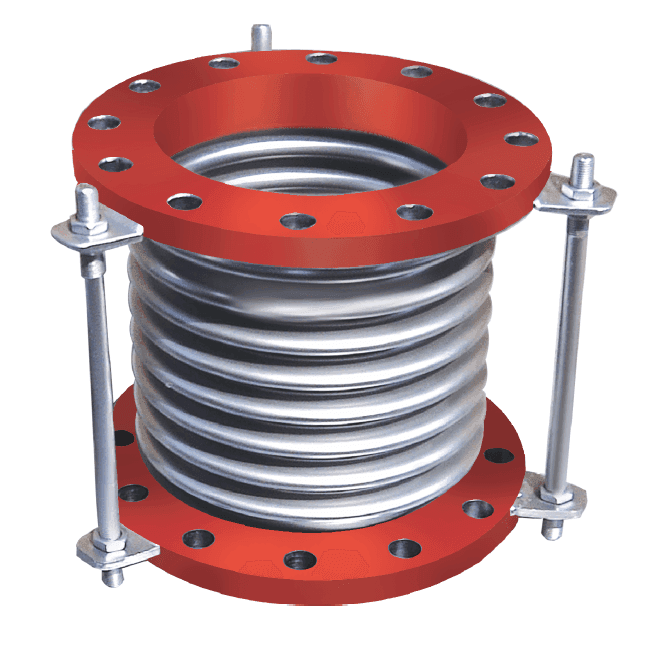

Metallic Expansion Bellow with Floating Flanges

Overview

Metallic expansion bellows with floating flanges are flexible pipe joints manufactured from stainless steel bellows elements with loose (floating) flanges. The floating flange design allows for easier installation on existing piping and compensates for angular and lateral misalignment. Suitable for high temperature, high pressure and corrosive applications.

Features

- Stainless steel bellows (304, 316, 321 grades)

- Loose floating flanges for easy installation

- Single or multi-ply bellows construction

- Compensates for axial, lateral and angular movement

- High temperature and pressure capability

- Corrosion-resistant construction

- Custom designs available

Applications

- Industrial process piping (chemical, petrochemical)

- Steam and condensate systems

- Hot water and thermal oil piping

- Exhaust and flue gas ducting

- Power plant piping systems

- Turbine and compressor connections

- High-pressure industrial applications

Technical Specifications

- Material: SS 304, SS 316, SS 316L, SS 321, Inconel

- Flange Standard: BS10, ANSI B16.5, BS4504

- Size Range: DN25 (1″) to DN1500 (60″)

- Pressure Rating: PN10 to PN40

- Temperature: Up to 600°C

- Bellows Plies: Single or multi-ply (2-3 plies for higher pressure)

- End Connections: Floating flanges, tie rods optional

Advantages of Floating Flanges

- Easier installation – flanges rotate freely

- Compensates for angular misalignment

- No need for precise pipe alignment

- Suitable for retrofit and replacement applications

- Reduces installation time and cost

Benefits

- Absorbs thermal expansion in piping systems

- Reduces stress on equipment and pipe supports

- Suitable for high temperature and pressure service

- Corrosion-resistant stainless steel construction

- Long service life with proper installation

- Manufactured to international standards

Contact RMS Corporation for metallic expansion bellow selection, movement calculations and engineering drawings for your piping application.