Description

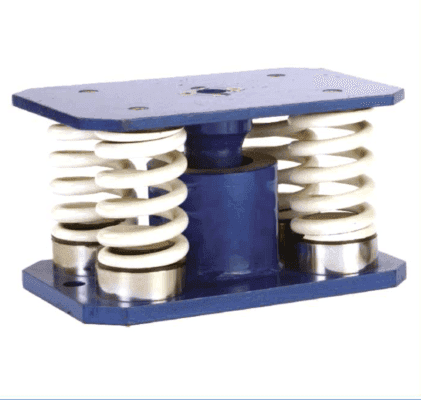

Spring Viscous Damper – Heavy Duty Vibration Control

Overview

Open spring viscous dampers combine spring vibration isolation with viscous damping technology to provide controlled vibration reduction for heavy machinery. The four-spring design distributes loads evenly while the viscous damping mechanism controls transient vibrations and resonance.

Features

- Open-spring configuration for stability and load distribution

- Integrated viscous damping for transient vibration control

- Heavy-duty construction for industrial applications

- Corrosion-resistant finish

- High load capacity

Applications

- Large industrial presses and stamping equipment

- Heavy forging and forming machinery

- Impact loads and shock-producing equipment

- Large compressors and reciprocating machinery

- Seismic isolation applications

- Test rigs and dynamic equipment

Technical Specifications

- Load Range: 500 kg to 7800 kg per damper

- Deflection: 25mm to 50mm

- Damping: Viscous fluid damping mechanism

- Temperature: -20°C to +80°C

- Material: Steel springs, steel housing, damping fluid

Benefits

- Controls vibration and shock loads effectively

- Reduces resonance and transient vibrations

- Protects equipment and building structure

- Long service life with minimal maintenance

- Suitable for harsh industrial environments

Contact RMS Corporation for spring viscous damper selection and technical specifications.