Description

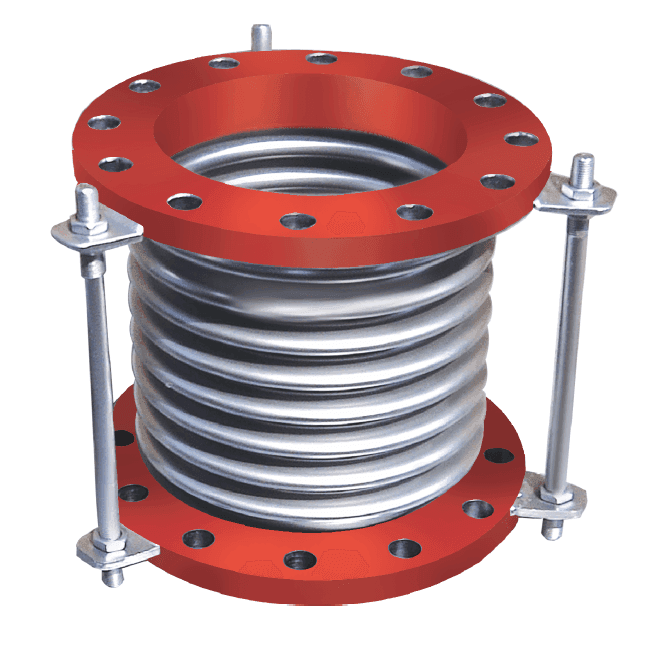

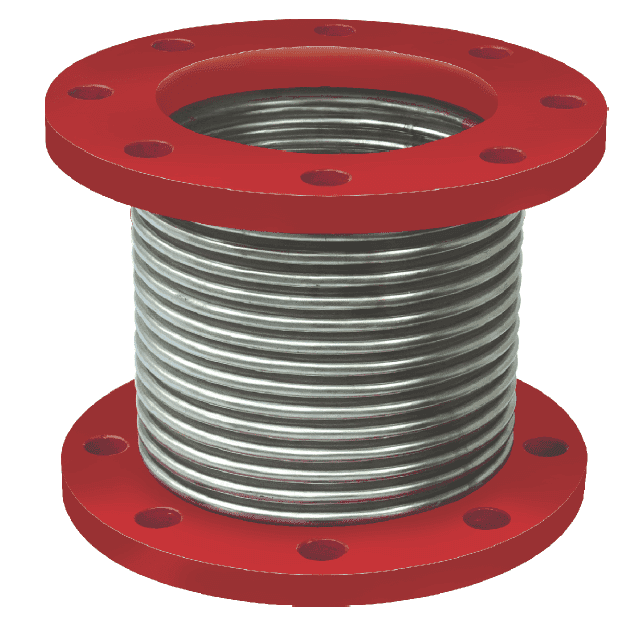

Axial Bellows – Metallic Expansion Bellows

Overview

Axial bellows are flexible metallic expansion bellows designed to absorb axial movement (compression and extension), lateral deflection and angular rotation along the pipe axis. These bellows are manufactured from stainless steel (304, 316, 321) and can be supplied with flanged ends or butt weld ends to suit your piping configuration.

Features and Construction:

- Single bellows element welded to flanges or pipe ends

- Available in single axial bellow and double axial bellow configurations

- Optimum finish with precision welding and leak testing

- Excellent vibration resistance and fatigue life

- Precise dimensions manufactured to industry standards

- Custom designs available per customer specifications

Applications:

- HVAC chilled water and condenser water piping systems

- Industrial process piping requiring thermal expansion compensation

- Pump discharge and suction connections

- Steam and condensate piping systems

- High-temperature exhaust and flue gas applications

- Petrochemical and chemical process piping

- Power plant piping and turbine connections

Technical Specifications:

- Material: Stainless Steel 304, 316, 321 or special alloys

- Pressure Rating: Up to 40 bar depending on size and design

- Temperature Range: -200°C to +600°C (higher on request)

- End Connections: Fixed flanges, floating flanges or butt weld ends

- Design Standards: EJMA, ASME Section VIII, BS 6129

Benefits:

- Absorbs thermal expansion and contraction in piping

- Reduces stress on equipment and pipe supports

- Compensates for misalignment during installation

- Long service life with minimal maintenance

- Suitable for high pressure and high temperature service

Contact RMS Corporation for selection assistance, movement calculations and custom axial bellow designs.