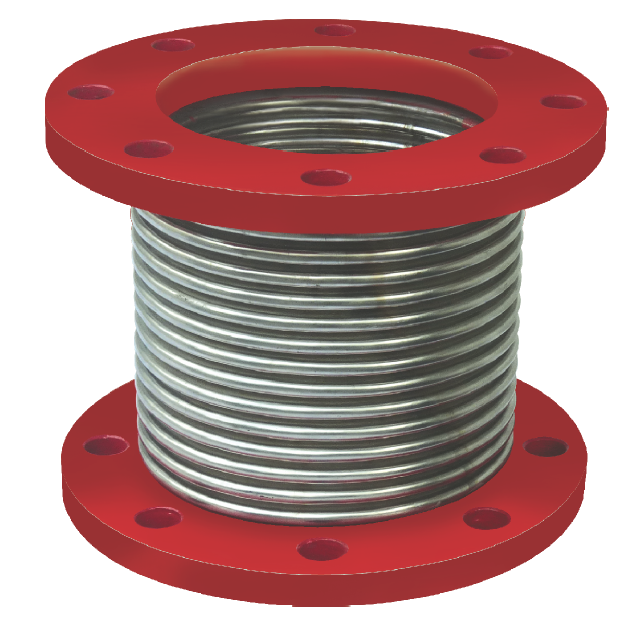

Description

Double Arch Rubber Expansion Bellows are an assembly which are used primarily in piping applications to compensate for thermal expansion and contraction, reduce noise and vibration produced by the rotating element as well as relieve pipe stress during operation.

Our Double Arch Rubber Expansion Bellows is designed to withstand temperature up to 70°c and pressure up to 40 bar. It also helps to absorb thermal expansion. These bellows are used in heating, ventilating systems, vehicles exhaust connectors, nuclear fusion etc.

Some of the features are as follows:

- Eliminates stresses of expansion & contraction

- Compensates for misalignment – axial, lateral, angular & torsional

- Absorbs vibration & shock

- Eliminates line noise

- Prevents pipe bucking & fracture

For More Details: CLICK HERE