Description

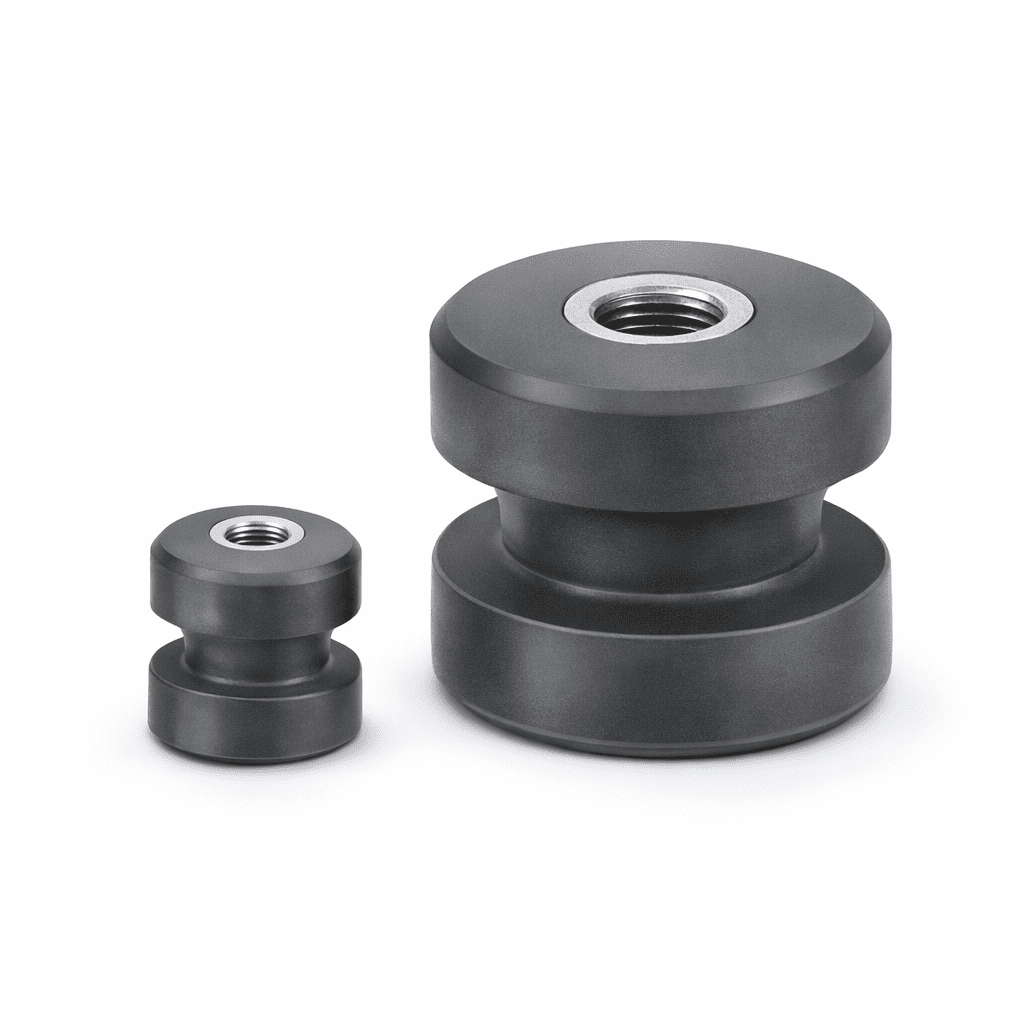

Dual Compression Mounts – Enhanced Rubber Vibration Isolators

Overview

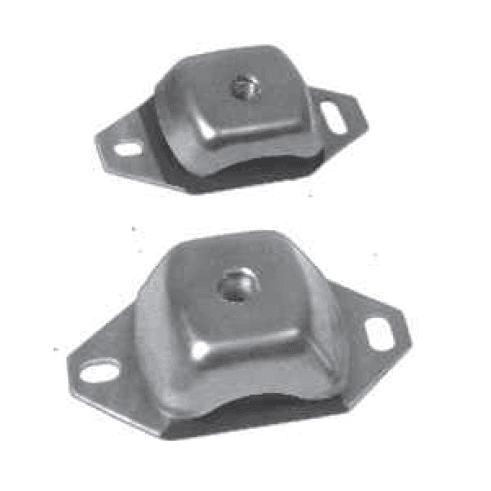

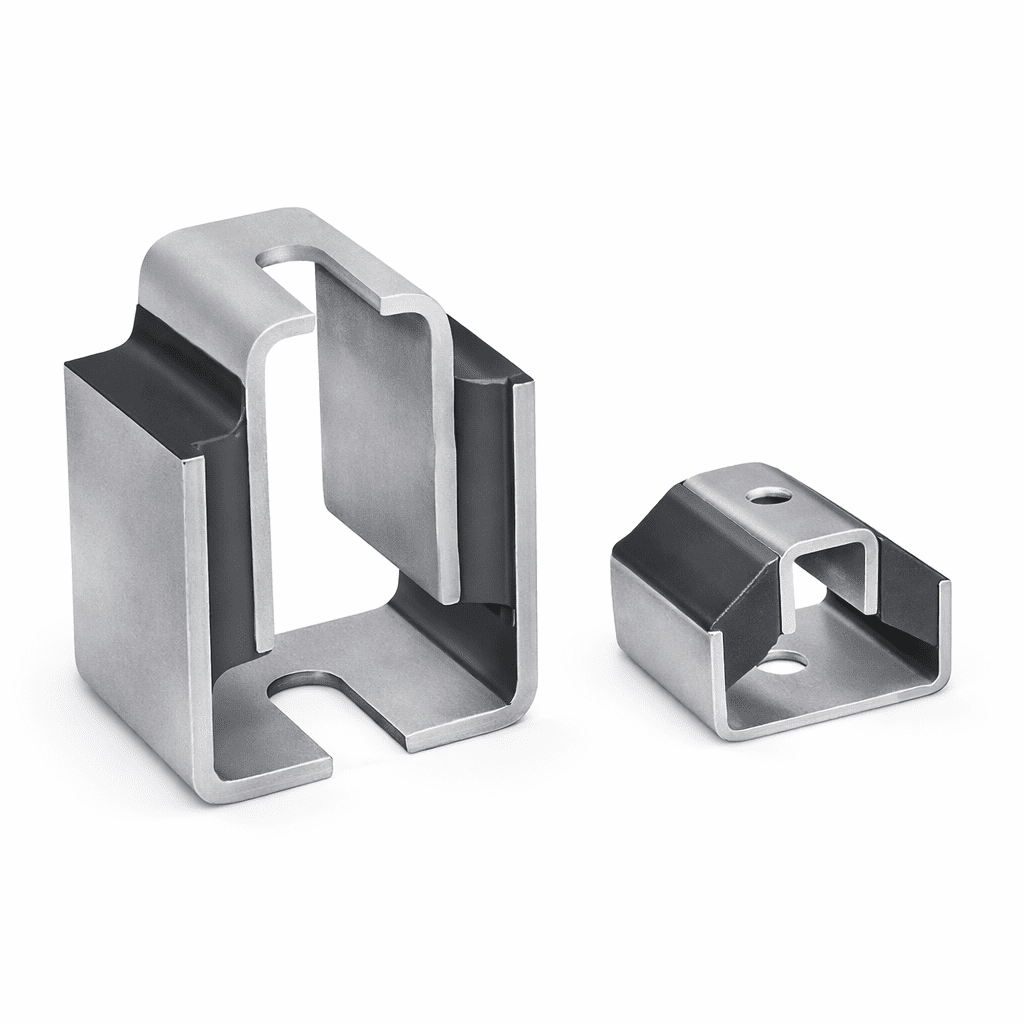

Dual compression mounts feature two rubber elements working in compression to provide enhanced vibration damping and isolation. The dual rubber design offers improved stability and load distribution compared to single rubber mounts, making them suitable for equipment with moderate to heavy loads and vibration levels.

Features

- Dual rubber element construction

- Enhanced vibration damping characteristics

- Stable mounting with even load distribution

- Rugged steel housing and mounting plates

- Corrosion-resistant protective coating

- Multiple sizes and load capacities

- Suitable for harsh industrial environments

Applications

Dual compression mounts are used for:

- Centrifugal pumps and gear pumps

- Industrial fans and blowers

- Small to medium compressors

- Electric motors and motor-driven equipment

- Radiators and Engine Mounts

- Packaging and material handling equipment

- Vehicle Chassis for Engine Loading

Benefits

- Superior vibration isolation with dual rubber design

- Improved stability prevents rocking

- Even load distribution extends mount life

- Reduces vibration transmission to floor

- Lowers noise levels in equipment areas

- Easy installation with standard hardware

- Long-lasting performance

Selection

Choose dual compression mounts based on:

- Equipment weight and center of gravity

- Operating speed and vibration frequency

- Required isolation efficiency

- Mounting space and configuration

Contact RMS Corporation for dual compression mount selection and vibration isolation advice.