Description

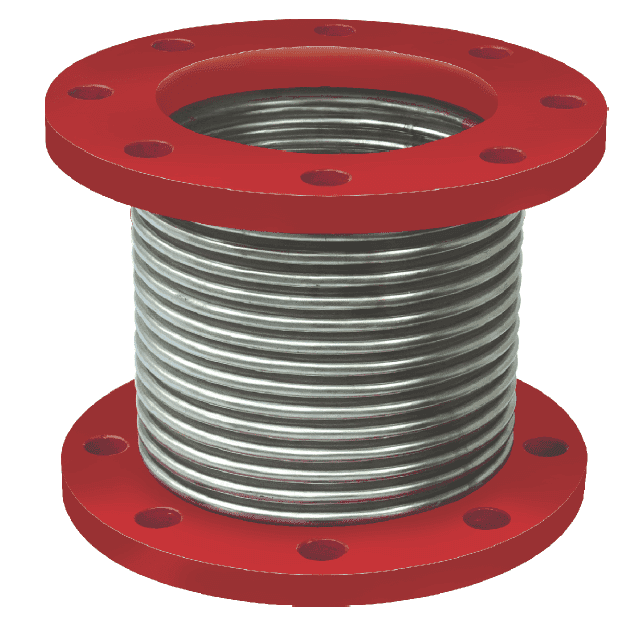

Metallic Expansion Joints with Fixed Flange

Overview

Metallic expansion joints with fixed flanges feature stainless steel bellows elements permanently welded to fixed flanges. This construction provides a leak-tight, robust connection suitable for high pressure, high temperature and critical service applications where maximum reliability is required.

Features

- Stainless steel bellows welded to fixed flanges

- Single or multi-ply bellows construction

- Leak-tight permanent flange connection

- Suitable for high pressure and temperature

- Corrosion and erosion resistant

- Pressure tested and certified

- Manufactured to international standards

Applications

- HVAC chilled water and hot water systems

- Steam and condensate piping

- Industrial process piping (chemical, petrochemical, pharmaceutical)

- Power plant piping and turbine connections

- Boiler feed water and condensate return

- Exhaust systems and flue gas ducting

- High-pressure and critical service applications

Construction Types

Single Ply Bellows: One layer of stainless steel – suitable for lower pressures, maximum flexibility.

Multi-Ply Bellows (2-3 plies): Multiple layers for higher pressure rating and increased safety factor.

With Liner/Sleeve: Internal flow liner prevents turbulence and protects bellows from erosion.

Benefits

- Permanent leak-tight flange connection

- Maximum reliability for critical applications

- Suitable for high pressure and temperature

- Corrosion-resistant stainless steel

- Absorbs thermal expansion and vibration

- Reduces stress on equipment and piping

- Manufactured and tested to international codes

Quality Assurance

- Material certifications

- Hydrostatic pressure testing

- Visual and dimensional inspection

- Helium leak testing (on request)

- Radiographic testing (on request)

- Full traceability and documentation

Installation Guidelines

- Align piping carefully before bolting flanges

- Use proper gaskets and bolt torque sequence

- Allow clearance for bellows movement

- Install limit rods if provided

- Use pipe guides and anchors per design

- Do not use bellows to correct major misalignment

Contact RMS Corporation with your piping specifications (size, pressure, temperature, media, movement requirements) for metallic expansion joint selection, engineering calculations and certified drawings.